Gamma Rays Story

"Technology for better life"

Soyagreentec

Radiation has existed naturally since ancient times, and even today it is naturally received every day,

but it can be made artificially as the nuclear technology develops.

There are radioactive isotopes of this kind called cobalt-60 (CO-60).

The use of gamma-ray light from here for medical, food, pharmaceutical, cosmetic, and other health industries makes it environmentally friendly, insecticidal, sterilizing, and sterilizing.

Currently, sterilization methods that are being used are used with the disadvantages of residual toxic substances and environmental destruction. In order to solve these problems, major countries of the developed countries in the world are using gamma sterilization technology widely and increasing their use more and more.

What is gamma-ray irradiation technology?

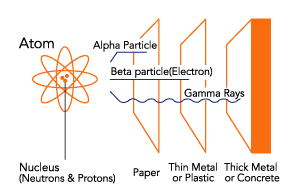

Types of Radiation

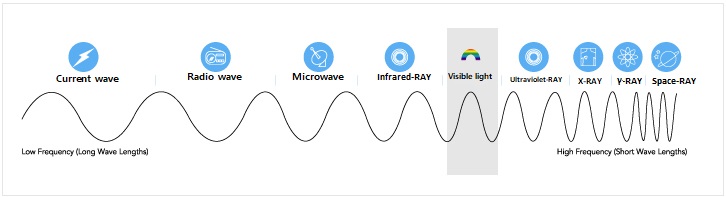

Soyagreentec use gamma-ray energy, which is known for its eco-friendly advanced technology. Gamma rays are electromagnetic energy emitted from cobalt 60, such as sunlight (visible light), microwaves in microwave ovens, and diagnostic X-rays in hospitals.

Gamma rays have a strong permeability, so any encapsulated packaged product can penetrate into the interior to kill or destroy harmful microorganisms or pests, but it does not leave or produce any substance harmful to human health

Advantages of Gamma Irradiation

Warranty

- Pests, pathogenic microorganisms, general bacteria, fungi and spores are sterilized and sterilized.

- Temperature, and physical (impact), so the product can minimize deformation and component destruction.

- The process is carried out in the state of goods receipt (sealed state) and full mark, and no secondary contamination occurs.

- Any kind of packaging can be sterilized effectively.

- It is possible to produce products with no preservatives and no preservatives in foods, cosmetics and pharmaceuticals.

- Extension of validity period is possible

Cut down the money

- Cost reduction is possible by omitting the self-cultivated plant by a single treatment.

- You can get better effects and better characteristics.

- Compared to other sterilization methods, packaging design cost can be reduced by using various packaging design.

- In international trade, quarantine and clearance can be simplified to save time.

- PRODUCT RELEASE is possible through sterilization validation and evaluation of doses without the use of aseptic test and BI (biological indicator) in daily management

Comparison of current sterilization, sterilization methods and characteristics of irradiation with irradiation method

| Item | High-pressure steam | EO GAS | Gamma ray | Electron beam |

|---|---|---|---|---|

| Sterilization certainty | Relatively Sure | EO GAS processing require penetration in products | Most Sure | Relatively Sure |

| Processing time | A few minute | A few hours | A few seconds ~ A few hours | A few seconds ~ A few hours |

| Product Materials | Heat resistance martials | Wide Range | non denaturation radiation resistant materials | non denaturation radiation resistant materials |

| packing type | vapor permeability(NARROW) | EO GAS permeability(Narrow) | Full Packing (Wide) | Full Packing (Wide) |

| Material permeability | Small | Not sterilization to seal structure | complete penetration | depends on density |

| Interaction | Gas disassemble | Hydroxyethylation | radiolysis | radiolysis |

| after Control | drying / cooling process | 1week degassing | none | none |

| Product safety after processing | none | Toxicity(bellowing EO Standard Level) | none | none |

Prospects for the use of radiation technology

Utilization in the food industry

- The long-term safe storage of food resources is possible through the removal of agricultural and livestock products, the death of contaminated organisms, and the suppression of growth, contributing to the increase of food use and price stabilization.

- With the death of pathogenic microorganisms, it can be used as a substitute for more safe food production, prevention of food-controlled diseases, and use of chemicals.

- It is a very effective method for public health as a quarantine management technology for international food trade.

- This technology can be used to replace existing food processing and processing problems and to produce new processed products.

Widespread use in the medical device, pharmaceutical and cosmetics industries

- It may replace the controversy over the harmful and adverse effects of chemical additives such as preservatives and preservatives.

- The safety issue of the quality and sterilization method of the medical product can be solved by using ISO 11137 International Standard for Medical Products and KGMP Rule safely.

Radiation is the safest, environmentally friendly,

and most effective sterilization technology to date,

and a reliable food storage technology.

With high oil prices approaching, the era of using technology to destroy the global environment, such as heat, chemicals, and oil energy, will lose competitiveness and disappear. In the future, nuclear energy, one of the things that will replace the technology that affects environmental degradation and the freezing era, will be the forefront of this era of eco-friendly gamma ray technology